About hard agave

Thorntail Hard Agave? It’s in a league of its own! While tequila, a close cousin, follows the path of fermentation and distillation, our Hard Agave takes a different route. Instead of distillation, we stop at fermentation, resulting in a drink that’s not just flavorful but also lightly carbonated. It brings a clean, vibrant buzz that keeps the good vibes going all day long!

How It’s Made

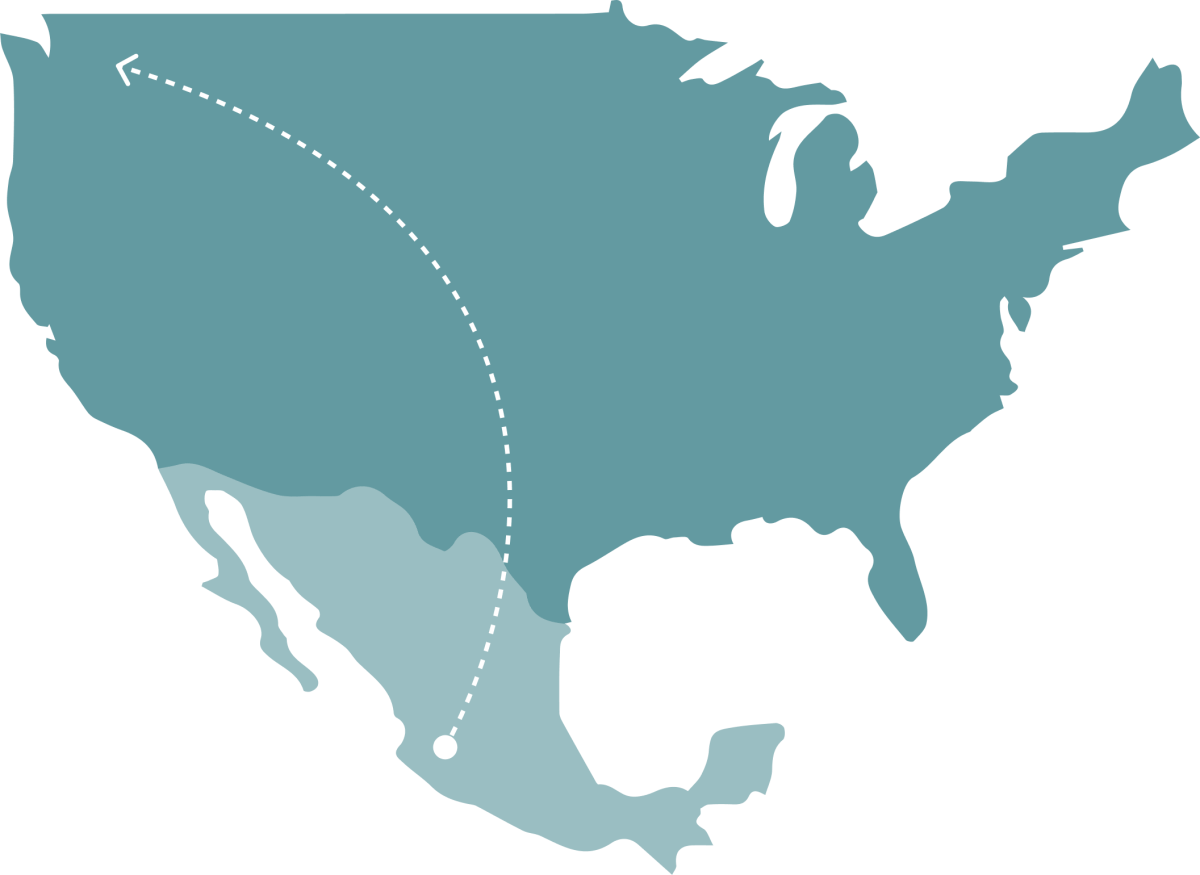

The Blue Weber agave plant is grown in the hills of Capilla de Guadalupe in Jalisco Mexico for a minimum of 4 years.

The Piña’s then get baked in a brick oven for 24 hours. (It is here that the plant’s starches convert into sugars.)

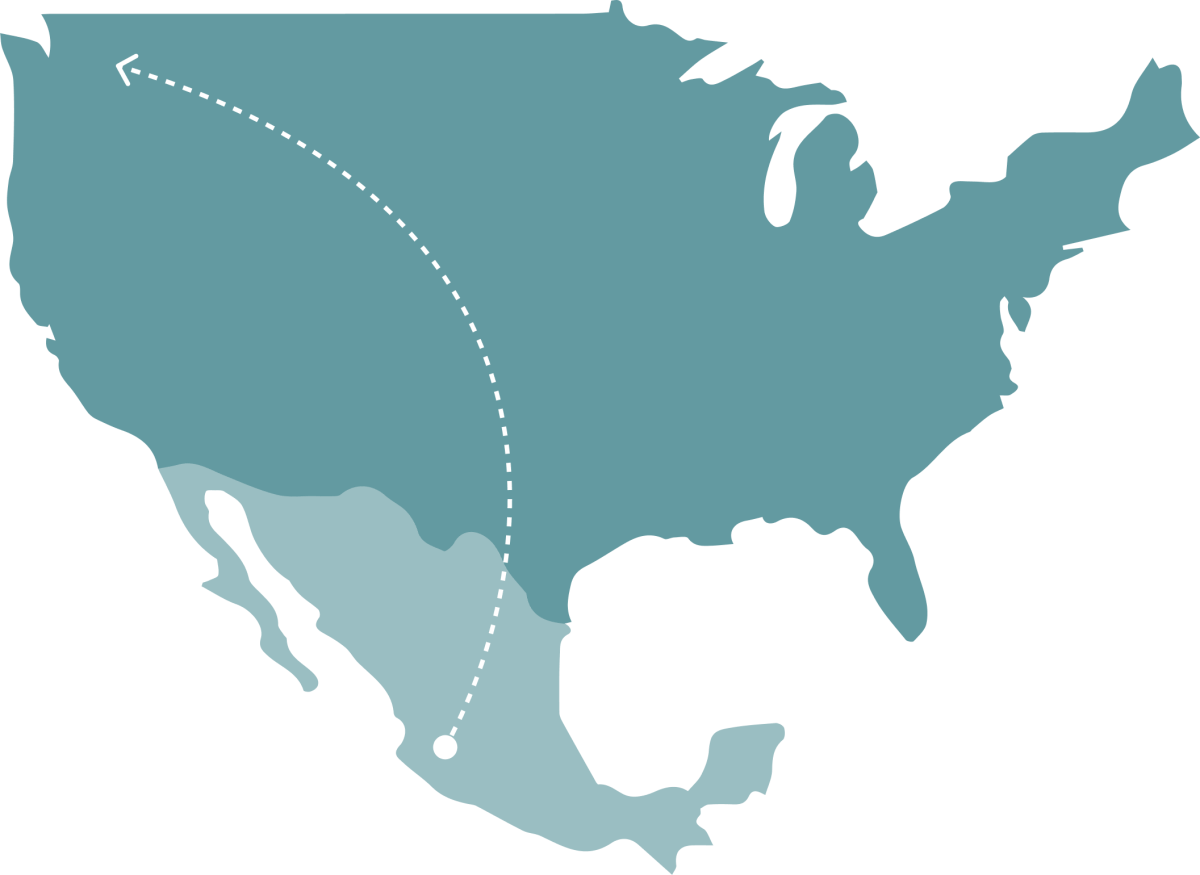

After liquid is extracted, it is loaded on a truck and shipped to Seattle.

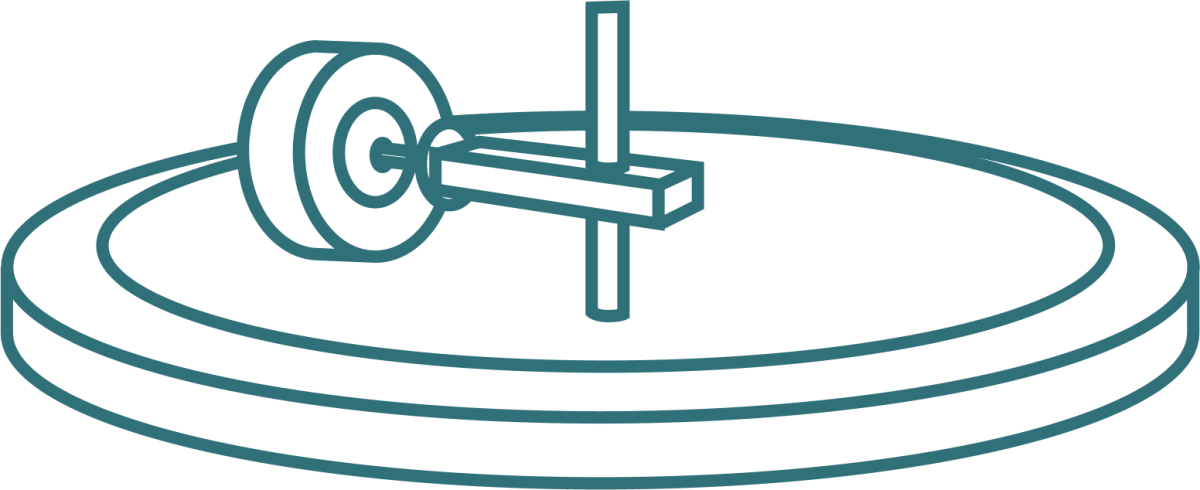

After being cooled, the fermented agave is ran through a centrifuge to separate the yeast / clarify the liquid.

The liquid/hard agave is lightly carbonated

The Jimador then comes through the field with a sharp tool called a “Coa” and de-leaves the agave plants and shapes it into a perfect Pina.

It is then shredded into bits, pressed to extract all the sugar from it and filtered, resulting in 100% agave nectar.

The agave nectar is combined with boiling water, yeast, and nutrients and fermented for 5-9 days

A small amount of real fruit concentrate, sea salt, and citric acid are added to make each flavor

Then it’s packaged in cans and prepared for shipping to stores

The Blue Weber agave plant is grown in the hills of Capilla de Guadalupe in Jalisco Mexico for a minimum of 4 years.

The Jimador then comes through the field with a sharp tool called a “Coa” and de-leaves the agave plants and shapes it into a perfect Pina.

The Piña’s then get baked in a brick oven for 24 hours. (It is here that the plant’s starches convert into sugars.)

It is then shredded into bits, pressed to extract all the sugar from it and filtered, resulting in 100% agave nectar.

After liquid is extracted, it is loaded on a truck and shipped to Seattle.

The agave nectar is combined with boiling water, yeast, and nutrients and fermented for 5-9 days

After being cooled, the fermented agave is ran through a centrifuge to separate the yeast / clarify the liquid.

A small amount of real fruit concentrate, sea salt, and citric acid are added to make each flavor

The liquid/hard agave is lightly carbonated

Then it’s packaged in cans and prepared for shipping to stores